|

|

|

| NUMROTO

|

|

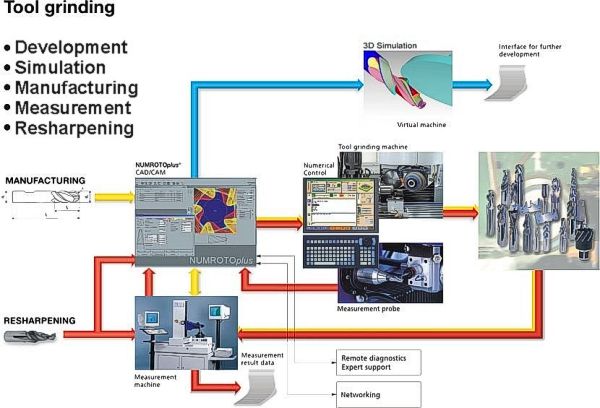

NUMROTO - 25 years high-end technology in tool grinding

NUMROTOplus? is a software package for producing and resharpening a whole range of tools.

It allows you to program your grinding machine directly at a PC and provides you with programming support in the form of graphical help screens and well-designed user interfaces.

When working on complex machining tasks, the programmed tool may be examined and optimized before grinding starts by using the high-precision simulation facility.

Measurement of tools

When resharpening tools it is important that as many dimensions as possible are automatically measured by the probe or another measuring device. This saves time and avoids input mistakes.

Using a measurement probe

NUMROTOplus? incorporates ingenious measurement cycles which allow a single probe to measure many dimensions.

Measuring machine interface

NUMROTOplus? is also able to import data from a measurement machine. Additional values can be generated and directly imported as with the probe It is also possible to use one measurement machine together with several grinding machines. This makes for more efficient use of the measurement machine and means that grinders are used for grinding alone.

2-D Simulation

The 2D simulation is an integral part of NUMROTOplus, and is contained in each NUMROTOplus package. All grinding operations can be simulated on the PC using the 2D simulation. The tool can be cut in a desired position so that the subsequent cross-section can be evaluated and measured. Even details as small as a few micrometres can be analysed.

Afterwards, the tool cut on the machine corresponds to the simulated tool exactly. In this way, machine and wheel inaccuracies can also be found and dealt with.

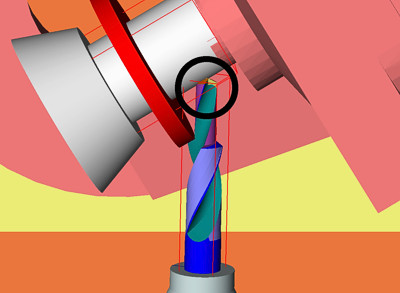

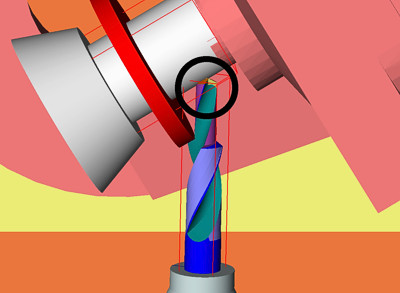

3D Simulation and 3D Collision Monitoring

With the integration in the NUMROTO software of 3D tool simulation with grinding process animation and collision monitoring with 3D machine simulation, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience.

In addition to the 2D simulation, NUMROTOplus can also be equipped with the integrated NUMROTO 3D software. As with the 2D option, this software provides a perfect simulation of the complete tool.

Even with the best software and experienced personnel, collisions are sometimes unavoidable. An unused wheel, spindle arbor or attached auxiliary device (tailstock, support) are all possible causes of a collision. To prevent this, NUMROTO and NUMROTO 3D come complete with an integrated collision check, which can also be fully automated.

|

|

|

|

|