| myMaker - Events - Chinese Version |

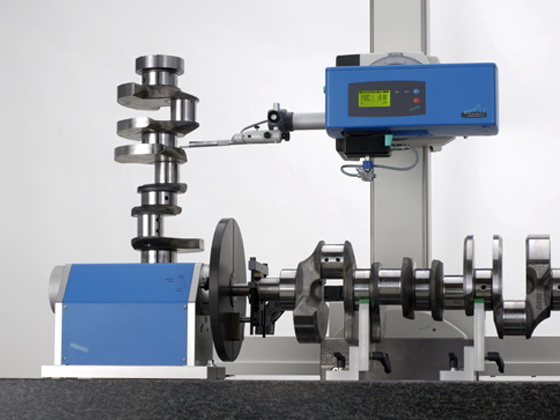

| Home > Cutting Tools > Measuring & Gauging Tools > HOMMEL-ETAMIC T8000 wavemove |

|

|

| About newMaker | Gold Suppliers | Contact Us | showsbee.com | showseye.com | newMaker China | My newMaker |

| © newMaker.com. All Rights Reserved |

µsurf cylinder - measurement of cylinder running surfaces

µsurf cylinder - measurement of cylinder running surfaces TIGO SF CMM

TIGO SF CMM Leitz SIRIO Xi

Leitz SIRIO Xi Outside Micrometer - Submicrometer MDH

Outside Micrometer - Submicrometer MDH Three-Point Internal Micrometers - Borematic

Three-Point Internal Micrometers - Borematic