|

|

|

| ePD Plastic Metallisation

|

|

Under the technology brand ePD™ , Oerlikon Balzers develops integrated services, equipment and solutions for the metallisation of plastic parts.

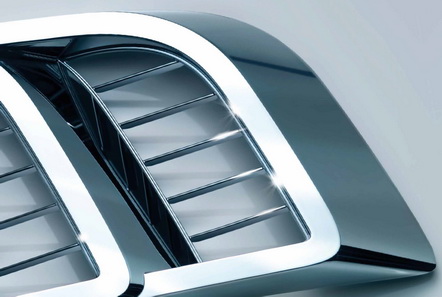

ePD™ is the short form for embedded PVD and signifies an environment-friendly and future-oriented coating procedure. Whenever high-end metallic surfaces on plastic parts are requested - ePD™ is the more environmentally friendly alternative compared to out of date metallization techniques. No harmful agents such as chromium III and chromium VI or other heavy metals are used in the process. As such the technology is especially renowned for its environmental neutrality and its extended functionalities in a variety of industries among them the automotive industry, the furniture industry and even the sanitary industry.

What is ePD™?

Under the technology brand ePD™, Oerlikon Balzers develops integrated services, equipment and solutions for the chrome looking metallisation of plastic parts.

ePD™ is the short form for "embedded PVD for Design parts" and signifies an environment-friendly and future-oriented coating procedure. Whenever high-end metallic surfaces on plastic parts are requested - ePD™ is the clean alternative compared to today''s electro plating technologies. No harmful chemicals such as Cr6+ are used in the process. The ePD™ process is environmentally friendly due to low energy consumption and the avoidance of special waste. ePD™ coated parts are fully recyclable.

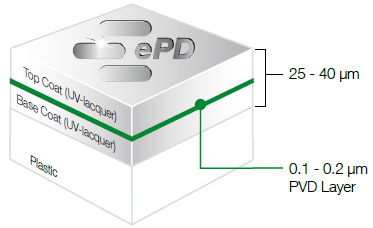

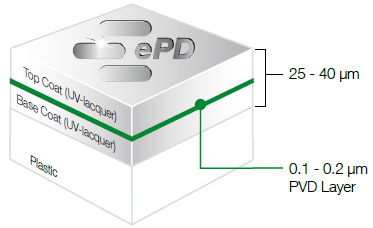

PVD layer between Base and Top Coat (UV lacquer) The new process is described as "embedded PVD for Design parts", since the metallisation effect is sandwiched between two layers of UV lacquer. The first layer is the primer, or base coat, which serves to equalise irregularities on the surface of the injection-moulded plastic substrate. On top of this comes the actual inline PVD, which uses magnetron sputtering in a vacuum chamber for an exceptionally stable coating with high microstructure density-with no harmful ions left behind. To protect the metallized coating, a final UV coating (top coat) is applied which is extremely durable, stable and, fast-drying.

|

|

| Related Products |

|  INGENIA - The compact coating system: fast, precise, flexible INGENIA - The compact coating system: fast, precise, flexible

Oerlikon Balzers Coating AG

INGENIA, Oerlikon Balzers' new compact coating system outperforms previous systems as regards speed, precision, and flexibility; it features simpler handling ... | |  Venjakob VEN SPRAY ROBOT Venjakob VEN SPRAY ROBOT

Stiles Machinery Inc.

Not long ago, robots were perceived as a threat to painters'' jobs. Today, manufacturers realize that without robotic automation they may not be able ... | |  Venjakob VEN DRY UV Venjakob VEN DRY UV

Stiles Machinery Inc.

UV curing paint systems are hardened within seconds by intensive UV radiation. These systems permit short production processes requiring little space. ... | |  aluminum profile sand blasting machine aluminum profile sand blasting machine

Brightstar Aluminum Machinery Co., Ltd

Aluminium profile sand blasting machine function

Brighstar Aluminum profile sand blasting machine is the special equipment for the surface of the aluminum ... | |  aluminum polishing machine aluminum polishing machine

Brightstar Aluminum Machinery Co., Ltd

Aluminum polishing machine description

Brightstar Aluminum polishing machine is one kind of machine for the surface treatment of aluminum profiles. ... |

|

|

|

|

INGENIA - The compact coating system: fast, precise, flexible

INGENIA - The compact coating system: fast, precise, flexible Venjakob VEN SPRAY ROBOT

Venjakob VEN SPRAY ROBOT Venjakob VEN DRY UV

Venjakob VEN DRY UV aluminum profile sand blasting machine

aluminum profile sand blasting machine aluminum polishing machine

aluminum polishing machine