|

BHS-Sonthofen: Taking filtration to the limits

5/6/2014 |

|

|

Filtration technology in industry: Clear filtrate and minimal disposal volumes, even with the finest particles in low concentration

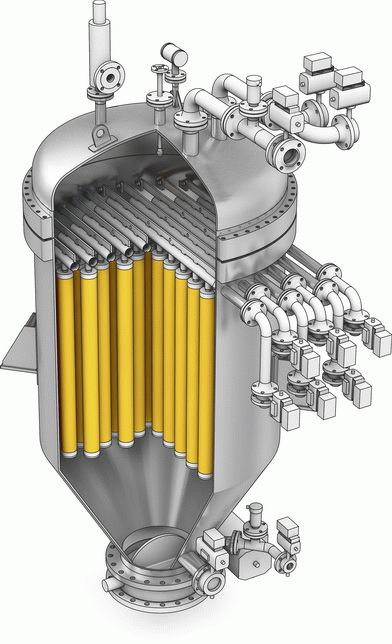

At this year's IFAT in Munich, BHS-Sonthofen is exhibiting candle filters from the further developed CF series for cleaning industrial waste water. They are particularly suitable for purification of industrial waste water with low solids content and reduce disposal costs to a fraction.

The BHS candle filters of the CF series have been specially developed for filtration of liquids with solid concentration of less than one percent, i.e. an area of limited cake building capabilities in which other filters fail. Even in the case of very fine particles with low solids content, they produce a clear filtrate. With filter areas ranging from 1 to 150 m2, they are designed for hourly throughput rates of up to several hundred m3.

One special feature of the BHS candle filter is filtered solids do not form a sludge, but a pre-dried, semi-solid filter cake with a solids content of between 50 and 80 percent. BHS thus significantly reduces the disposal volume compared with filter types with solids contents of 10 to 20 percent. There is no need for further treatment of the filter cake, which can be disposed directly.

The filters work automatically - no additional effort for exchanging and disposing of cartridges, or filter materials for deep bed filters is necessary.

BHS offers a broad range of process solutions based on candle filters for solid-liquid separation. Upstream and downstream process steps include pre-thickening, precoating and deep bed filtration or polishing-filtration. The result is always a clear filtrate.

Typical applications for BHS candle filters are:

Regeneration of industrial waste water in the chemical and pharmaceutical sectors

Regeneration of gray water in coal-to-gas plants

Recovery of abraded catalyst particles

Cleaning of amine solution from gas scrubbers

Desulfurizing of natural gas in the "amine sweetening process"

Treatment of the amine solution in the removal of sulfur dioxide from power station flue gases

Cleaning of electrolytes in galvanizing plants in the steel industry

BHS-Sonthofen offers standardized candle filter plants comprising the main components candle filter, piping with fittings and measuring instruments, steel construction and and control systems.

Background

The BHS candle filter is an automatic, batch-operated filter bed with vertically arranged filter elements. The suspension is fed into the pressure vessel and continuously pumped. The filter cake is formed on the outside of each filter candle. The filtrate is discharged from the inside of the candles through immersion pipes. After filtration, the filter cake can be washed, reslurried or dried. Finally, the cake is lifted by a blast of compressed air and discharged.

The candle filter is a compact unit with standardized modules that can be combined flexibly according to the specific requirements of the process. On request, BHS provides complete installations including fittings, instrumentation, piping, pumps, tanks, steel construction and control systems. The plants consist of modules designed for easy transport and assembly. That reduces the customer's planning effort and allows preassembly at the factory as well as comprehensive testing prior to shipment (FAT). On-site installation time is thus reduced and short overall delivery periods are possible.

BHS is represented with two booths at IFAT: the company is exhibiting filter plants for industrial waste water applications in Hall A1 and showcasing recycling technology in Hall B2. |

|

Related Exhibition:

|

|

|

|

|

IFAT 2014

|

World's Leading Trade Fair for Water, Sewage, Waste and Raw Materials Management

5/5/2014 - 5/9/2014

Venue: New Munich Trade Fair Centre, Munich, Germany

|

|

|

|

|

|

|