|

EPC 60 Retrofit enhances control of previous generations of marine centrifugal separators

5/15/2012 |

|

|

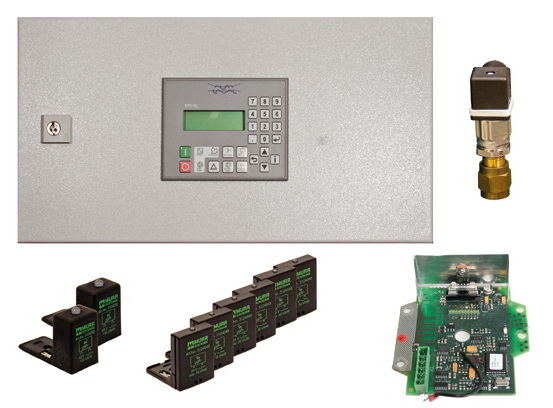

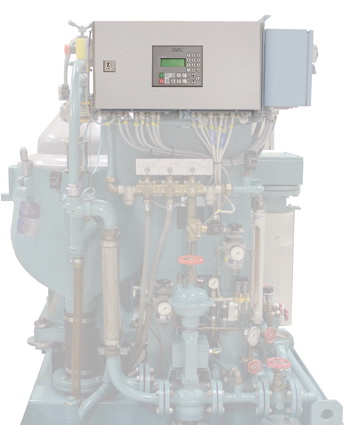

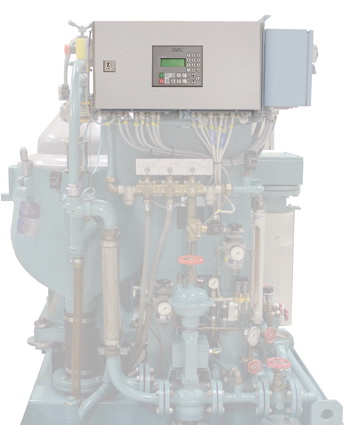

Alfa Laval announces the introduction of its EPC 60 Retrofit, a new upgrade kit intended to enhance older control systems of previous generations of Alfa Laval centrifugal separators with the modern EPC 60 control unit. The retrofit kit provides a viable alternative for owners of 30-year-old Alfa Laval centrifuges to modernize the entire separation system with a marine-approved PLC system with modular I/O cards. Upgrading an aging control system delivers significant financial gains in the form of improved system reliability, a secure spare parts supply and more uptime.

The Alfa Laval EPC 60 Retrofit kit offers a hardware and software upgrade that enhances the control systems, including the IPC 231, EPC 30, EPC 41 and EPC 400, of a wide array of older Alfa Laval separators. These robust separation systems, such as the Alfa Laval MAPX, WHPX, MOPX, FOPX, LOPX and MFPX, were developed in the 1970s and 1980s, and their aging control systems pose risk to reliable operation.

"Upgrading older Alfa Laval control systems secures the reliability and extends the service lifetime of the entire separation system. In addition, it raises product quality, increases production capacity and delivers more uptime," says Magnus Nordin, General Manager, Parts & Service, Marine & Diesel Equipment, Alfa Laval. "This has a direct impact not only on return on investment but also on the bottom line."

Introducing modern PLC functionality to older generations of Alfa Laval separators is cost-effective and hassle-free, since everything conveniently fits within the existing space. Simply mount the EPC 60 cabinet with its modular I/O cards into the space occupied by the old control cabinet. There is no need to replace the heater, steam control valve or power unit cabinet, starter cabinet and piping, and no welding is required.

"The EPC 60 Retrofit kit makes operation and troubleshooting much easier than before," continues Nordin. "The user interface on the EPC 60 is very intuitive and easy to operate. It gives the operator easy access to operational information securing an efficient and trouble free operation. The EPC 60 can very easily be connected to the central computer for remote supervision giving the operators access to all the operational information."

In short, the combination of space-saving design, modular I/O cards and ease of operation and maintenance makes the EPC 60 Retrofit kit a solid choice for extending the life of older separation systems.

For more information, please visit us at www.alfalaval.com/marine. |

|

|

|

|

|