|

Faster and smarter tubular parts production

8/29/2014 |

|

|

At FABTECH, Unison will be demonstrating the versatility of all-electric tube bending technology with a Breeze machine suitable for bending tubes and pipes up to 2 inches in diameter.

August 28, 2014 - Leading tube bending machine manufacturer Unison will be demonstrating the breadth of technology that it provides for right-first-time manufacture of precision tubular parts at FABTECH. Exhibit highlights include the first showing in the US for a novel manually-powered but CNC-controlled tube bender for low volume work, advanced 3D simulation software for efficient offline development of production-ready bending programs, and a highly versatile all-electric machine from the company's Breeze range of tube benders.

The main exhibit on Unison's booth - C564 in Hall C - will be an all-electric Breeze machine suitable for bending tubes and pipes up to 2 inches in diameter. The machine will incorporate multi-radius/multi-stack tooling, allowing Unison to demonstrate its ability to create complex tubular part shapes with multiple tightly-spaced bends very efficiently, with minimal set-up time, operator involvement or material scrap. These attributes make this type of machine popular with companies handling high volume, small batch size production of parts, especially if they are using expensive specialist materials such as titanium or Inconel. All of the machine's motion axes, including its direct acting clamp and pressure dies, feature CNC controlled precision servomotors to facilitate fully automatic setup and ensure extremely accurate and repeatable bending.

Unison will also show a brand new version of its EvBend 1000 low-cost tube bender, which is currently under development. Designed specifically for precision low-volume manufacturing and prototyping applications, this manually-operated CNC tube bender will incorporate a new high performance controller, featuring a highly intuitive touch-sensitive user interface and network interfaces for ready integration with other manufacturing machines and CAD systems.

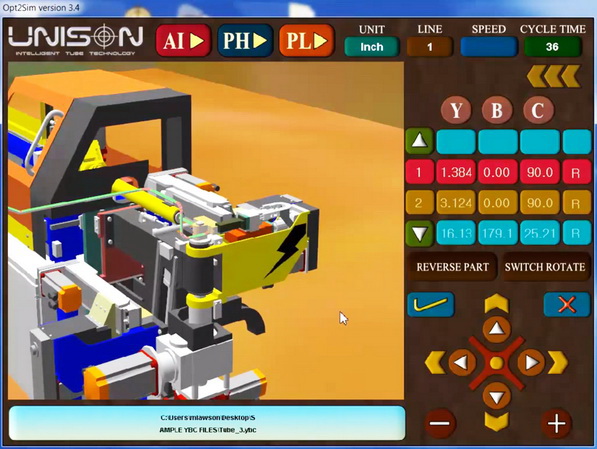

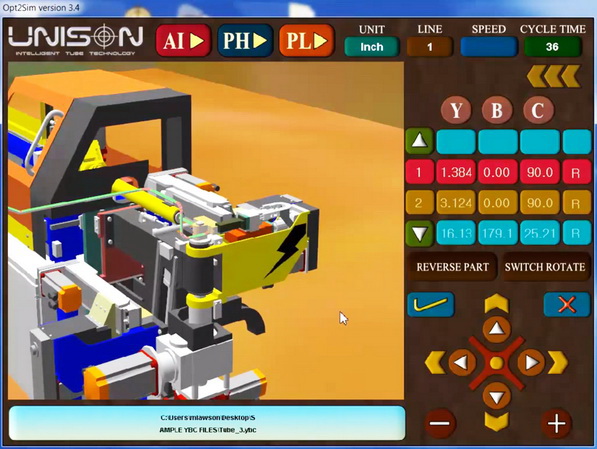

Unison will be showing the latest version of its advanced Opt2Sim 3D tube bending machine simulation software at FABTECH.

Another key element of Unison's 2014 exhibit will be advances in CAD/CAM software for tube bending projects. To help customers shorten the time needed to create production programs - and quote on new jobs - Unison will demonstrate the latest version of its advanced 3D simulator, Opt2Sim. This powerful PC-based simulation software enables users to fully analyse, optimise and validate control programs for bending machines very easily and without access to the physical machine. Featuring a proprietary precision physics engine with an accuracy of just plus/minus 0.005 mm, the simulator uses artificial intelligence techniques to evaluate the most efficient way of bending a part on a target machine, automatically modifying the YBC bending data as necessary to create error-free production-ready programs.

Based on true CAD models of real machines, the software simulates every single moving component, with comprehensive monitoring to guard against tube collision. Realistic imagery enables users to visualise the entire bending sequence in considerable detail and in real-time. The latest version of Opt2Sim will simulate any model from Unison's extensive Breeze range of all-electric tube benders, which covers tube sizes from 5/8 to 7 inches, and when running in high speed batch mode can typically process about 100 bending programs an hour. |

|

Related Exhibition:

|

|

|

|

|

FABTECH 2014

|

metal forming, fabricating, welding and finishing event

11/11/2014 - 11/13/2014

Venue: Georgia World Congress Center, Atlanta GA, United States

|

|

|

|

|

|

|