|

igus Simply plugged-in: The readychain speed

5/9/2014 |

|

|

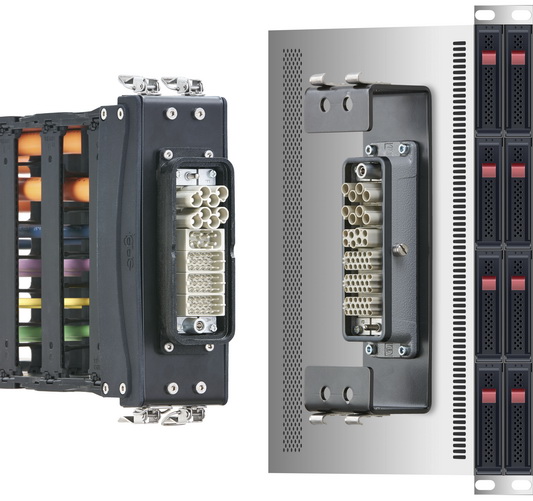

The new plug-in energy chain "readychain speed" connects harnessed e-chainsystems within seconds and without the need for tools.

Supplying energy made easy with the plug-in module from igus

The plug-in energy supply system "readychain speed" from igus connects harnessed e-chainsystems within seconds without using tools. This approach reduces lead times in assembly operations and machinery downtime to a minimum.

The objective of any igus readychain is to make module assembly as easy as possible. A new igus system revolutionises harnessed energy chains: "readychain speed". The design-engineers combined connectors and mounting brackets into one unit that can be directly plugged into the control cabinet. This connects readychain speed harnessed e-chainsystems in seconds without using tools.

Short lead times and low machinery downtimes

Generally, pre-harnessed modules have the benefit that production process use a fully tested component, and that all components are compatible with each other. This smooth process is particularly important in cycletime-based or assembly line operations. In comparison to individual components, readychain modules only need a fraction of the assembly time. Using readychain speed from igus, lead times are yet again reduced significantly. This means that significantly more machines can be built in the same time, while keeping production floorspace and labour capacity the same.

readychain speed is also welcome in production lines that make high-value products at mid-sized unit volumes or low-cost components in large volumes and at high speeds: e-chains with the plug-in energy chain can be exchanged conveniently and within seconds during the production process. This approach reduces machinery downtime to a minimum.

Assembled in seconds without tools

For quality assurance reasons, manufacturers initially assemble machinery at their facility. They are then dismantled for delivery to the customers and subsequently re-assembled at their destination. This process is very time consuming and can damage the machine. Assembly and dismantling is accomplished faster and more reliably with the simple plug-in mechanism used by readychain speed. The connectors make assembly particularly easy: FOC, control, servo, data, and pneumatic lines can no longer be dislocated during transport. Moreover, no special qualification is needed to install the plug-in readychain speed system since the compact module can be installed entirely without tools. |

|

|

|

|

|