|

|

|

| PRIAMUS Fill Hotrunner interfaces

|

|

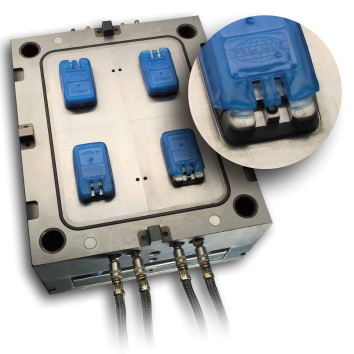

Automatic hotrunner control

- Mulit cavity molds

- Multi component molds

- Cluster molds

- Family molds

- Weld lines

- Sequential molding

- Integrated process monitoring

An uncontrolled melt flow is a main problem with many injection molding applications. PRIAMUS Fill analyzes with cavity temperature sensors the filling of each cavity and adjusts, if deviations occur, the set value temperature of the hotrunner nozzle automatically until a balanced condition is achieved.

PRIAMUS Cool

Process depending mold temperature control

- Automatic balancing of mold surface temperature

- Uniform temperature distribution on the mold surface

- Closed loop

- Balanced / optimized shrinkage conditions

- Single or multi cavities

A non-uniform temperature distribution over the mold surface leads to different shrinkages of the molded part. PRIAMUS Cool measures and analyzes the cavity temperatures in every temperature controlled zone and corrects automatically every single cooling circuits until a uniform temperature distribution on the molds surface is achieved.

PRIAMUS Fill & Cool, Compact Version

Small, compact and with online viscosity monitoring

PRIAMUS Fill & Cool Compact Version has in principle all basic functions of the PRIAMUS Fill & Cool standard system. However a limitation is given in the maximum number of channels (max. 8 channels) as well as in the control of digital switching signals.

PRIAMUS Fill controls, monitors and balances the melt flow in hotrunner molds.

Depending on the application cavity temperature sensors are installed either in every cavity (multi cavity and family molds) or at different positions in the same cavity (sequential applications, weld lines). PRIAMUS Fill analyzes the temperature information and changes the set values of the hotrunner controller automatically until balanced conditions in different cavities or a reference condition in the same cavity are achieved. For process optimizing and monitoring functions it is recommended to use additional cavity pressure sensors.

The idea of melt flow control

Melt flow in a cavity changes permanently depending on different melt viscosities. The only possibility to control melt flow is to make sure that the melt front reaches the same position at the same time. Cavity temperature sensors measure a temperature increase as soon as the melt arrives. PRIAMUS Fill analyzes the temperature signals automatically and calculates how the set values of the nozzles must be changed in order to achieve respectively control the desired viscosity (i.e. the correct melt front velocity).

PRIAMUS Cool ??Process depending mold temperature control

Besides the optimized fill conditions it is the temperature on the mold surface which mainly influences the part shrinkage and its final properties. Non-uniform temperature distribution over the mold surface inevitably leads to different shrinkage of the molded part ??and therefore to different dimensions and warpage. PRIAMUS Cool analyzes the measured cavity temperatures automatically and corrects the single cooling circuits until a uniform temperature distribution on the mold surface is achieved.

It does not make any difference if this relates to separate cooling circuits of multi cavity molds or to cooling circuits of large area parts such as bumpers or instrument panels.

|

|

| Related Products |

|  MuCell® Molding Technology MuCell® Molding Technology

Trexel, Inc.

The most significant plastic processing

innovation in the last 20 years

The MuCell® microcellular foam injection molding process for thermoplastics ... | |  injection tooling injection tooling

F&S Tool, Inc.

F&S Tool offers quick turnaround prototypes to completely interchangeable high-cavitation tooling (cavity to cavity and mold to mold).

Our routine ... | |  Plastic Seals Mould Plastic Seals Mould

ZheJiang HuangYan Younger Mould Co.,Ltd.

The product will not be distortion under -45celsius degree to +50celsius degreeThe surface is printed mark, series number and barcode by stamping or laser. ... | |  Cable Ties Mould Cable Ties Mould

ZheJiang HuangYan Younger Mould Co.,Ltd.

Rich experience in cable ties mould, export more than 250sets Cable tie mould every year.

OEM and ODM offered

Design according customer''s request.

... | |  SAVE the Planet SAVE the Planet

Frigel Firenze SpA

High Precision Controllers for High Temperatures

The TRP series of Thermogel units are pressurized water temperature controller with indirect cooling. ... |

|

|

|

|

MuCell® Molding Technology

MuCell® Molding Technology injection tooling

injection tooling Plastic Seals Mould

Plastic Seals Mould Cable Ties Mould

Cable Ties Mould SAVE the Planet

SAVE the Planet