|

|

|

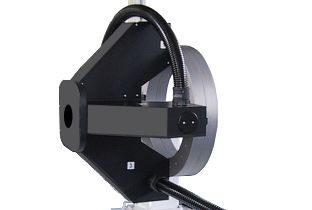

System for inline surface inspection of plastic hoses

Model: PSP-H400

|

|

PSP-H400 for Plastic Hoses

PSP-H400 is a turn-key-ready system for the inline inspection of plastic hoses. Advanced inspection algorithms in combination with fast line-scan cameras and special LED-lights enable that even the smallest surface defects can be automatically detected and marked on the hose. In addition to its outstanding performance the main emphasis was laid upon the user-friendly operator interface (touchscreen operated) and a robust design. Switching between products can be done within seconds, since all product specific parameters are stored in recipe files. PSP-H400, with its slim footprint, can be intergrated in any hose extrusion line. Touchscreen/Computer unit and main sensor ring can also be separated, for installation in places with space constraints. Special guides to stabilize the hose can be mounted on the left and right side of the system sensor head.

How it works

PSP-H400 uses up to 4 camera modules, which are mounted on a circular instrument ring. The hose runs during production centered through the instrument ring and through the opening of a special designed LED-illumination device. The camera modules scan continuously the surface of the profile and send the surface data in real-time to the central processing unit. All detected surface irregularities are classified according to predefined defect criteria.

PSP-H400 is operated completely via the central 15" touchscreen. The user interface was designed with the goal that any operator can use the system intuitively without extensive training. The operator defines for every hose type a product specific recipe and adjusts the quality parameters for this hose manually one time. The operator sets the inspection borders for each camera unit just by tapping on the desired surface areas on the touchscreen. The system automatically adjusts the light sensitivity for achieving the optimal inspection performance. All parameters are automatically stored in the recipe file and are used whenever this specific product is in production. |

|

| Related Products |

|  PSP-M400 for Plastic Profiles PSP-M400 for Plastic Profiles

Pixargus GMBH

System for surface inspection of miscellaneous plastic profiles

PSP-W400 was designed for the inline surface inspection of PVC window profiles. Surface ... | |  ProfilControl 5 for Rubber Profiles ProfilControl 5 for Rubber Profiles

Pixargus GMBH

The inline system for surface inspection of rubber profiles

ProfilControl 5 is a turn-key-ready system for the inline inspection of rubber extrusion ... | |  Conical Twin Screw Extrusion System Conical Twin Screw Extrusion System

Milacron Plastics Machinery

The Conical Twin Screw TC Series

Compact Designs Optimize Processing via Natural Compression

Cincinnati Milacron?? TC Series of Conical Twin Screw ... | |  Medium ULTRA Standard Extruders Medium ULTRA Standard Extruders

American Kuhne, Inc.

Medium ULTRA extruders are fixed horizontal extruders ranging from 2.0" to 4.0" (or 100 mm) diameter, any L/D, vented or non-vented. ULTRA extruders are ... | |  Medium ULTRA CR Corrosion Resistant Extruders Medium ULTRA CR Corrosion Resistant Extruders

American Kuhne, Inc.

Medium ULTRA CR Corrosion Resistant extruders are fixed horizontal extruders ranging from 2" to 4" (100 mm) diameter, any L/D. They are ideally suited ... |

|

|

|

|

PSP-M400 for Plastic Profiles

PSP-M400 for Plastic Profiles ProfilControl 5 for Rubber Profiles

ProfilControl 5 for Rubber Profiles Conical Twin Screw Extrusion System

Conical Twin Screw Extrusion System Medium ULTRA Standard Extruders

Medium ULTRA Standard Extruders Medium ULTRA CR Corrosion Resistant Extruders

Medium ULTRA CR Corrosion Resistant Extruders