|

|

|

| HEAVYGEL EFX - Industrial Water Cooled Water Chiller

|

|

With the new Water Cooled Chiller Heavygel EFX, Frigel sets new standards for Process Cooling, introducing the use of the most efficient technologies available today.

The introduction of High Efficiency Screw Compressor and Oil Free Centrifugal Compressor make available chillers with efficiency that cannot be compared with all the other traditional chillers.

HEAVYGEL EFX

THE MOST EFFICIENT CHILLERS IN PROCESS COOLING

In developing the new EFX chiller line, Frigel has paid utmost attention to the concept of "Total Cost of Ownership", well aware that the initial investment cost of a water chiller is a minimal part of the overall running costs that chiller will generate during its lifetime.

Energy use, installation, maintenance and dismantling costs, downtimes and service costs, must all be carefully considered and evaluated to make a smart decision when the time to invest in a new process chiller comes.

With the clear objective of minimizing the ??otal Cost of Ownership", for our Customers, we have designed the new EFX chiller line, with the following features:

MINIMUM ELECTRICAL CONSUMPTION

The Compressors of the EFX chillers have been selected according to the highest Energy efficiency obtainable today.

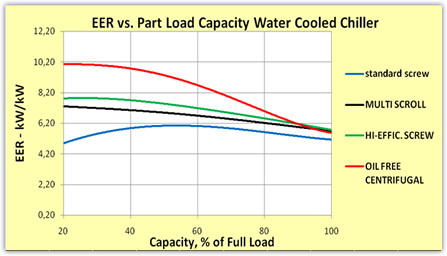

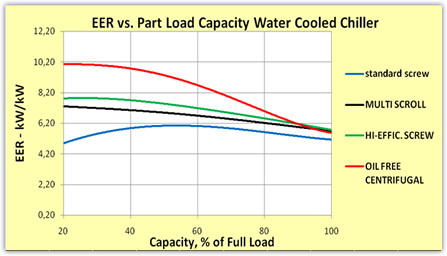

Note: EER (Energy Efficiency Ratio) indicates the electrical performance of a chiller.

The above chart shows the full and part load performance curves of the compressors used on the EFX chillers compared with a typical oil-flooded screw compressor on a 300 kW (90-ton) water-cooled chiller.

The three types of compressors used on the EFX chillers line are much more efficient compared to traditional compressors.

The Energy Savings that can be achieved with the EFX Chillers can widely justify eventual higher costs of the initial investment.

The amount of savings obviously depends on two variables: the cost of energy and the running hours.

The table that follows can give an idea of the impact of the energy consumption on the Total Cost of Ownership for a process chiller.

SIMPLE AND MODULAR INSTALLATIONS

EFX chillers are designed to minimize the footprint (almost 50% less than a standard water cooled chiller having same capacity) as well as installation and expansion costs.

Increasing Cooling Capacity is extremely easy, allowing an investment proportional to the need of the moment.

A remotable Control Panel manages all the plant: partializing capacity, equalizing the working hours for each unit installed, monitoring the alarms and all working parameters.

A remote control and management of the entire system through a Gateway is also available as an option (more information regarding this feature on last page).

Typical layout of installation of chiller EFX for a plastic injection moulding plant:

RELIABILITY

The choice of high quality components, the design, the control procedures during all assembling phases and a strict final test guarantee the maximum quality of final products.

Moreover, a guarantee of reliability for plants with EFX chillers is given by their modularity and redundancy, typical of all projects made with these machines. The presence of a simple stand-by EFX unit can drastically reduce the plant down-times risks.

EFX 150 MS - WATER-COOLED MULTI-SCROLL COMPRESSOR CHILLER

While the efficiency and reliability of the multi-scroll compressors featured in this unit has already been widely proved all over the world, we have thoroughly optimized its use for process cooling applications, with the intent of maximizing the energetic performances.

Optimized for use with R-407c refrigerant gas.

Very low start-up current.

High performance stainless steel brazed plate condenser and evaporator.

EFX 300 SC - WATER-COOLED HIGH EFFICIENCY SCREW COMPRESSOR CHILLER

employs a Semi-Hermetic High Efficiency Screw compressor, specifically designed for water cooled chillers with low gas compression ratio.

Optimized for use with R-134a refrigerant gas.

Very low start-up currents.

High performance stainless steel brazed plate condenser and evaporator.

EFX 300 TC - WATER-COOLED CENTRIFUGAL OIL-FREE COMPRESSOR CHILLER

This unit features the last generation of centrifugal compressor with Magnetic-levitation bearings.

It provides the best efficiency performance, particularly when operating with partial loads.

Turbine compressor system, driven by brushless motor with inverter.

Totally oil-free operation, thanks to rotation on magnetic bearings (Mag-Lev).

Reduced charge (70% less) of R-134a refrigerant gas.

Very low start-up currents.

Exceptionally silent operation.

Very Compact: 50% less footprint and reduced weight compared to traditional water cooled chillers.

High performance stainless steel brazed plate condenser and evaporator.

|

|

|

|

|

HEAVYGEL HGL - Industrial Air Cooled Water Chiller

HEAVYGEL HGL - Industrial Air Cooled Water Chiller