|

|

|

| FlexMT

|

|

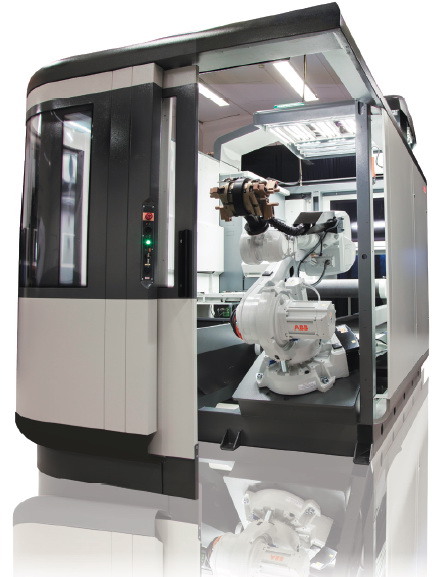

A leader in the development of automation solutions, ABB''s FlexMT sets the standard in flexible machine tool tending. This robotic solution increases machine utilization by as much as 60%. Available in two variants, the FlexMT 20 (20kg/1.65m reach) and the FlexMT 60 (60kg/2.05m reach), the FlexMT comes complete with a robot controller inside its fully integrated control cabinet. The FlexMT is a pre-engineered, well-tested and reliable automation solution.

There are three main benefits to using robots on the machine tool floor. These reasons include maximization of manufacturing productivity, reduction of operational and capital costs, and improved health and safety.

Maximization of manufacturing productivity

When compared with manual labor, robotic automation increases machine tool utilization up to 60 percent.

The nearly immediate payback - in some cases less than 12 months - is significant and tangible. The FlexMT from ABB provides reliable and predictable output from robot and machine tool. It facilitates higher machine tool utilization, up to a phenomenal 90 percent compared with traditional manual machine tools, which are in the range of 50 percent. This results in a much faster return on investment and gives a sustainable competitive advantage.

Reduction of operational and capital costs

The FlexMT is a standardized yet flexible solution that reduces operational and capital expenditures allowing a single person to operate several machine tools simultaneously. With the improved utilization and more efficient use of existing resources, the need for additional capital investment in new production equipment and peripherals declines.

Improved Health & Safety

The self-contained nature of the FlexMT improves working conditions by drastically reducing workplace injury related to heavy lifting, exposure to hazardous conditions including the presence of coolants, sharp edges, burrs, tooling and other dangers.

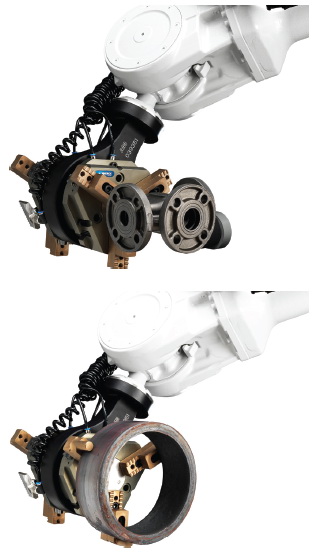

Designed to load and unload machine tools using visionguided robotics, the integrated solution is capable of handling a variety of additional manufacturing operations like marking,

deburring and cleaning with air. The FlexMT can run free from operator supervision for up to eight hours, depending on part size and cycle time, thanks to an internal buffering system.

The FlexMT is compatible with a wide range of machine tools, for example, horizontal and vertical lathes, machining centers and five (5) axis machines and grinders. Its numerous interfaces can be hardwired with 24V I/Os for easy communication with a machine tool.

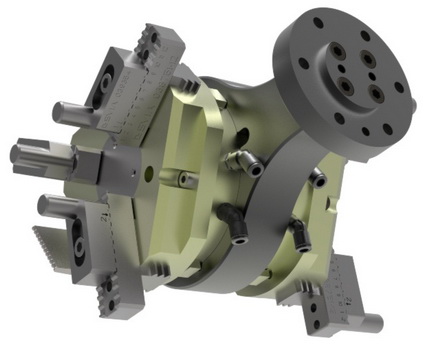

Capable of handling both small batch and volume production, the FlexMT comes equipped with a choice between a two- or three-finger gripper and six standard plug-and-play options, including: two separate deburring tools, a re-grip table,

marking unit, turn station, air cleaning box and a corridor/ passage.

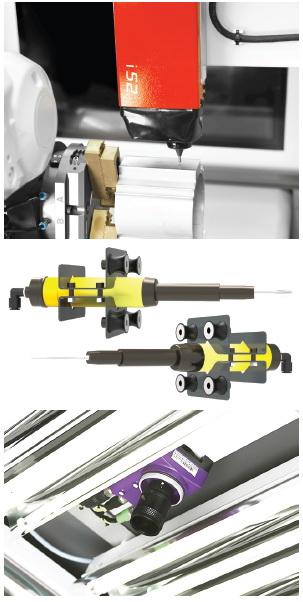

Vision-guided robotics

The FlexMT''s built-in vision system is specifically designed for robot guidance. Control and communications with the robot are tightly integrated into the software, a complete teach-in is very simple and intuitive from beginning to end. With one of the easiest to use operator interfaces on the market, teaching of a new part is possible in less than 10 minutes.

With the aid of vision-guided robotics, the FlexMT becomes even more flexible; able to recognize variations in part size and varying geometrical shapes. Additionally, parts need not to be fixed in a particular position to be identified and picked and placed by the robot, which reduces cost and complexity.

|

|

| Related Products |

|  IRB 1200 robot IRB 1200 robot

ABB Ltd.

Have you ever wanted to make your machines 15% smaller and 10% faster? ABB's IRB 1200 allows you to do exactly that. Specifically, it addresses the needs ... | |  Robot UR10 Robot UR10

Universal Robots A/S

Robots that are up and running in less than an hour

Your industrial robot can be up and running in less than hour - even by inexperienced users. They ... | |  UR5 - Robots that are up and running in less than an hour UR5 - Robots that are up and running in less than an hour

Universal Robots A/S

Your industrial robot can be up and running in less than hour - even by inexperienced users. They also offer unparalleled performance in precision handling, ... | |  Venjakob VEN SPRAY ROBOT Venjakob VEN SPRAY ROBOT

Stiles Machinery Inc.

Not long ago, robots were perceived as a threat to painters'' jobs. Today, manufacturers realize that without robotic automation they may not be able ... | |  KS Tool Changer 210 / 500 KS Tool Changer 210 / 500

KUKA Systems Group

The tool changer is designed for the automated changing of tools and workpiece carriers on the robot and is rated for a payload of up to 210 dN / 500 ... |

|

|

|

|