|

|

|

| Rotary Technology

|

|

Wheel Technology - Transforming One Industry After Another

The highly innovative Graham Wheel quite literally reshaped entire packaging markets by redefining the standards for high volume, high quality production. Today, this technology is in production on nearly every continent around the globe. With nearly 400 wheel installations worldwide, the Graham Wheel represents the unchallenged standard for high capacity with superior quality standards

GEC Rotary machines process a wide array of thermoplastics to produce containers from 100 ML up to 30 liters. GEC equipment conforms to many national and international safety and operating standards with certifications including OSHA and CE. GEC Rotary machines offer maximum flexibility for delivering ideal packaging solutions.

Indexing and continuous operating machines

Single and multi-cavity molds

Monolayer structures and coextrusion up to seven layers

In-mold labeling

View stripe enhancements

Aseptic blow Molding

GEC''s worldwide network of sales and service professionals work closely with customers to identify and install optimal production-machinery solutions and to provide responsive 24-hour support for reliable, consistent production line performance.

Single Flow Head Configuration

Our unique single head design extrudes the parison in an upward fashion, which permits the bottles to be discharged under the wheel in a simple operation. The upward extrusion of the parison also permits the parison program cylinder to be mounted beneath the head, thereby avoiding any possible contamination of the plastic by hydraulic fluid.

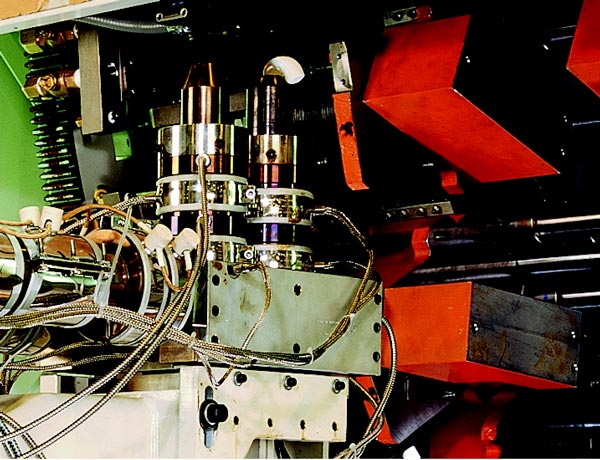

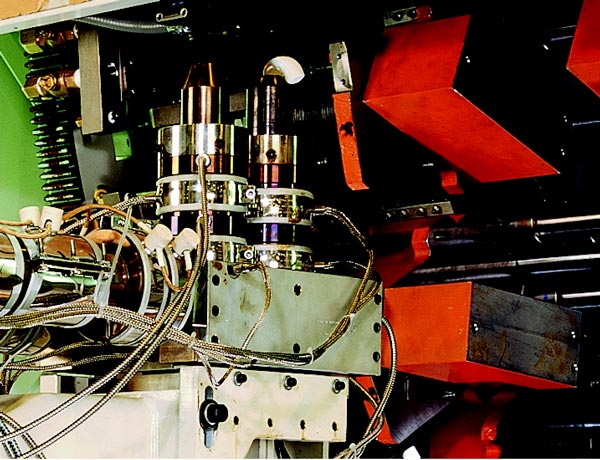

Remote Die Adjuster

Our patented remote die adjuster allows the operator to fine-tune the head for precise sidewall distribution without tools, and while the wheel is running.

Multi-Layer and View Stripe Options

All rotary machines are available with multi-layer and view stripe production capabilities. Our wide range of extruder sizes and flow head configurations allow up to seven layers of material distribution.

Typical applications include:

Detergent bottles with virgin inner and outer layers and a post-consumer scrap middle layer

Motor oil bottles incorporating a view stripe

Agricultural chemical bottles with up to six layers, including a barrier layer

Food and beverage long shelf-life packaging

Dual Parison

Dual parison technology can double the output of GEC Rotary machines when producing smaller containers.

Electro-Mechanical Operation

GEC Rotary machines operate completely electro-mechanically for quieter, cleaner and more efficient performance. Hydraulics are required only for the parison programmer and are positioned safely away from rotary components.

Modular Design

GEC packs a lot of production into its machines, with an emphasis on space-saving design.All machine controls, heaters and drives are mounted and prewired onto the extruder platforms for simple installation and maximum reliability.

Quick Changeovers

Many of our customers produce multiple containers on our rotary wheel machines. Some machines employ water lines into the platens, allowing rapid changeovers without water disconnects required. In other cases, GEC can employ our quick change "Shoe Mold" technology, allowing the removal of only the cavity insert ("shoe") portion of each mold when changing between products.

In-Mold Labeling

All GEC Rotary machines - continuous and indexing - can be equipped with IML (paper or film), a production capability unavailable on most other machine systems. Labeling takes place with virtually no loss in cycle time and with precise and consistent label placement accuracy.

One Conveyor, One Direction

Unlike dual station shuttle machines, our rotary machines require no reorienting state. Bottles exit the machine uniformly on a single conveyor.

GEC Rotary Deflash and Spin Trimmer with Trim Tooling

This proprietary technology provides the highest operational deflash trimming rates in the industry. This trimmer can handle speeds that would have required two or three linear deflash trimmers in the past.

Features include:

Horizontal, rotary based in-feed, deflash, transfer, trimming and out-feed sections

Spin trim or guillotine neck finish available - center or off-center neck

Mechanically cam driven actuation for long life and low maintenance

True perpendicular deflash - die tooling punches straight down on the container

Logs are fed into the trimmer from an accumulation queue via timing screws

Bottles exit the trimmer standing up (or laying down, if preferred), oriented as required

Rotary System Capabilities

Smallest Bottle - 82 ml (@ 7 grams)

Largest Bottle - 30 liter (@ 1,200 grams) |

|

| Related Products |

|  Industrial Blow Molding Systems Industrial Blow Molding Systems

Graham Engineering Corporation

GEC Industrial Blow Molding Systems are designed for the production of a wide range of industrial and technical parts including:

Automotive spoilers, ... | |  Shuttle Blow Molding machines Shuttle Blow Molding machines

Kautex Maschinenbau System GmbH

With its KLS, KCC und KEB series machines, Kautex is your partner for shuttle blow molders.

To meet the specific production requirements in the Industrial ... | |  3D Blow Molding Machines 3D Blow Molding Machines

Kautex Maschinenbau System GmbH

3D Blow Molding Machines for three-dimensional, convoluted Pipes

Conventional extrusion blow molding of heavily convoluted, three-dimensional tubular ... | |  Industrial Blow Molding Machines Industrial Blow Molding Machines

Kautex Maschinenbau System GmbH

Industrial Blow Molding Machines for technical Parts and Containers of up to 10,000 Liters Capacity (KBS)

With its many years of experience in building ... | |  Jomar Injection Blow Moulding Machine (IBM) Jomar Injection Blow Moulding Machine (IBM)

Jomar Corporation

Injection blow moulding is designed to create plastic bottles and containers that meet exacting standards with consistent weight, volume tolerance and ... |

|

|

|

|

Industrial Blow Molding Systems

Industrial Blow Molding Systems Shuttle Blow Molding machines

Shuttle Blow Molding machines 3D Blow Molding Machines

3D Blow Molding Machines Industrial Blow Molding Machines

Industrial Blow Molding Machines Jomar Injection Blow Moulding Machine (IBM)

Jomar Injection Blow Moulding Machine (IBM)