|

|

|

| Industrial Blow Molding Systems

|

|

GEC Industrial Blow Molding Systems are designed for the production of a wide range of industrial and technical parts including:

Automotive spoilers, duct work and reservoirs

Coolers/Chests

Swing sets, slides, bicycles

Medical parts

Housewares

Trash cans

Ornamental packaging

Water coolers and filtration containers

Industrial containers

Panels

Double wall parts

In-Mold Carpet, Vinyl and Component Insertion

GEC''s worldwide network of sales and service professionals work closely with customers to identify and install optimal production machinery solutions. GEC provides responsive 24-hour support for reliable, consistent production line performance.

Balanced Flow Distribution

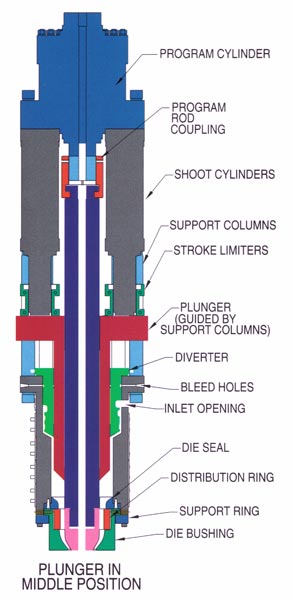

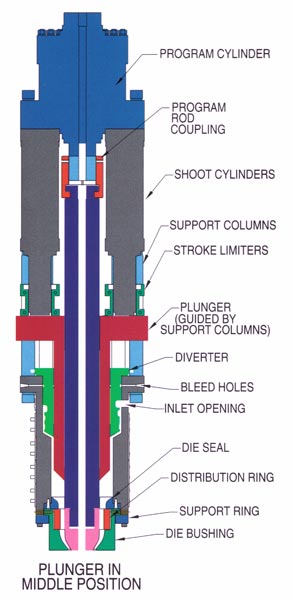

GEC design provides balanced flow distribution within the head that optimizes seamless material reknit. Fast material and color changes are accomplished by our self-cleaning plunger and the proven spiral diverter flow paths

Rapid Internal head cleaning

(Disassembly/Reassembly)

The head can be cleaned within an hour using standard hand tools. No major tools or special devices are required to accomplish this cleaning. The only parts that need to be removed from the machine are two small stroke limiters and a few bolts. On-board hydraulics perform the lifting task

First In-First Out Material Flow

Our uniform flow design eliminates stagnant areas, dead spots and flakes of burnt plastic, which prevents streaks and related defects. Fast and even parison drop and excellent concentricity assure the high quality parts you desire.

Unique flow ring

Wall thickness adjustments for parison curl are performed by four bolts that shift a flow ring in the bushing. The head tooling and program rod itself remain centered to the head.

Extrusion System

GEC Extruders are designed for maximum efficiency and dependable operation. System features include:

Water cooled grooved feed throat for consistent high output at low melt temperatures

Water or air closed loop barrel cooling

High efficiency screw design

Standard variable AC motor drive

Hopper magnets to protect the extruder and tooling

Single or dual extruders

Clamping System

GEC''s exclusive clamp design delivers unmatched production consistency and product quality. Clamping features include:

FEA designed clamping system with three tie bars designed to minimize deflection

Open press design facilitates mold changeover and part removal

Long life oversized bearings and guide rods

Servo valve actuation on presses for independent platen movement

Centerline platen stop with no "over travel" eliminates damage to molds, tooling, and blow ping

Automatic doors for safe operation

Regenerative hydraulic system with "kicker" cylinders for fast cycling, immediate tonnage and response time.

Press roll out feature

Motorized movement provides easy and safe access to the accumulator head and mold area for changeovers and for maintenance.

Press side-to-side adjustment

In-process press adjustments can be performed using this feature. This is particularly helpful in centering parisons to the mold cavities. Low-friction manual adjustments can be made with a small adjustable wrench.

Motorized up/down press adjustment

Allows process and machine adjustments to be performed quickly and easily, from either the operator station or an operator pendant. No need to loosen or tighten bolts.

Standard servo press design

The electronically controlled press allows individual press-half motion and platen position superior to mechanical synchronization while optionally providing asynchronous motion for use with non-symmetrical molds. This avoids any mechanical backlash from rack and pinion and enables the perfect condition for setting up blow pins.

Pneumatic System

Integrated controls and a flexible manifold design enables "plug and play" operation. Six valves are standard on single head machines, nine valves on dual head equipment. Additional valves are available as required.

Hydraulic System

The main hydraulic system is floor mounted for ease of maintenance and accessibility and its location eliminates troublesome topside leaks. A circulation pump ensures the continuous filtration and cooling of hydraulic fluid, extending machine life and ensuring uninterrupted operation. Servo solenoid valves are used for precision position and movement control.

Control system (XBM® Navigator)

Precision control and ease of operation are engineered into every GEC Accumulator Head machine. Control system features include:

Operator Friendly PC Control

Remote diagnostics

Onscreen parison profiling

Real time display of time, sequential function and alarm data

Programmable and savable press positioning, matched head filling and head shoot times

Fused Solid State contactors for precise temperature control

Plug-in interconnection for all major sub components |

|

| Related Products |

|  Shuttle Blow Molding machines Shuttle Blow Molding machines

Kautex Maschinenbau System GmbH

With its KLS, KCC und KEB series machines, Kautex is your partner for shuttle blow molders.

To meet the specific production requirements in the Industrial ... | |  3D Blow Molding Machines 3D Blow Molding Machines

Kautex Maschinenbau System GmbH

3D Blow Molding Machines for three-dimensional, convoluted Pipes

Conventional extrusion blow molding of heavily convoluted, three-dimensional tubular ... | |  Industrial Blow Molding Machines Industrial Blow Molding Machines

Kautex Maschinenbau System GmbH

Industrial Blow Molding Machines for technical Parts and Containers of up to 10,000 Liters Capacity (KBS)

With its many years of experience in building ... | |  Jomar Injection Blow Moulding Machine (IBM) Jomar Injection Blow Moulding Machine (IBM)

Jomar Corporation

Injection blow moulding is designed to create plastic bottles and containers that meet exacting standards with consistent weight, volume tolerance and ... |

|

|

|

|

Shuttle Blow Molding machines

Shuttle Blow Molding machines 3D Blow Molding Machines

3D Blow Molding Machines Industrial Blow Molding Machines

Industrial Blow Molding Machines Jomar Injection Blow Moulding Machine (IBM)

Jomar Injection Blow Moulding Machine (IBM)