|

In Mold Labeling (IML) Pilot Cell at StackTeck

5/31/2013 |

|

|

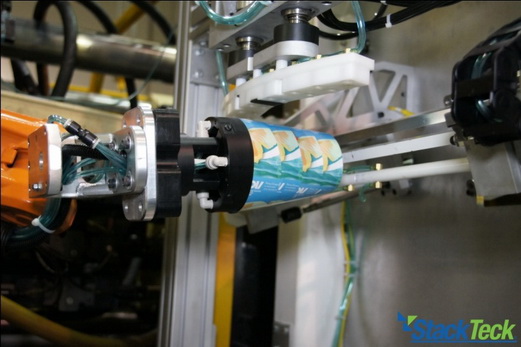

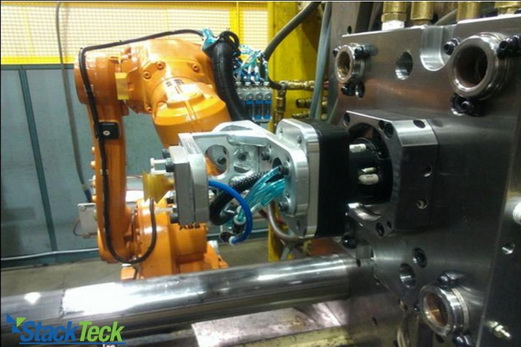

IML Pilot cell 6- axis robot holds mandrel at label loading position (close up at right). This robot is also capable of part de-molding and stacking on a conveyor (not shown). This cell is located at StackTeck's Technical Services Center, near Toronto in Canada.

"Getting IML parts to market with speed and cost-effectiveness"

StackTeck announces a new commitment for the existing IML pilot cell at StackTeck. As with previous generations of IML pilot cells, the third generation cell began using automation equipmentfromABB and CBW Automation.

Since the demand for IML prototyping has been continuous and growing, StackTeck has purchased the automation as a permanent assetthat will maintain the cell availability for customers on an ongoing basis.

The value of the IML pilot cell, is that it minimizes the cost of prototyping IML parts. A molder needs only to purchase molding surface components, a mandrel, and a magazine that are needed for a particular part. The rest of the hardware is already in place at StackTeck, including single cavity mold bases provided by StackTeck that are suitable for most packaging applications.

The current IML pilot cell is set up beside a 330T Husky test machine, however it is a flexible setup that can be moved to other machines when required. The system is equipped to run a single cavity mold, with automated handling of pre-cut labels, as well as part de-molding and stacking automation. StackTeck's Technical Services Center has 10 bays for mold testing and an additional 4 bays for systems integrations, with test machines ranging in size from 110T to 660T.

According to Randy Yakimishyn, President of StackTeck, "We're taking the initiative to work with leading suppliers to minimize our customers' up front costs involved with new IML product development. IML technology offers tremendous added value for injection molded parts, by enabling high quality decoration with a broad range of part design features, such as non-round shapes,tamper resistance, as well asspecialty labels. For two past projects, our customers have reported sales volume increases of 12% and 23%, following the introduction of a new IML package."

StackTeck's first IML pilot cell was set up in 2005, which supported many of the earliest large volume IML projects in North America. After it was purchased by a US customer, a second pilot cell was initiated in 2007. Over the course of the three pilot cells built to date, StackTeck has worked jointly with ABB, CBW Automation, Husky, Machines Pages, and Netstal; as well as other leading IML automation providers who sometimes provide mandrels and magazines for specific projects.

Robot places IML mandrel inside mold cavity for a wrap-around IML container, suction cup (at left) retrieves part from the core.

IML Pilot cell automation is floor mounted next to machine, a flexible solution that can be moved between machines.

For new product launches, the pilot cell allows for an early pre-launch simulation of how the production system will run at a later time. The currentIML Pilot Cell is a dedicated single cavity molding system, including automation for label insertion and part removal and stacking.

• Dedicated 330 US Ton Machine

• IML Robotics to handle single cavity molds

• Capable of all label types

StackTeck offers complementary services for plastic part design, label design, in addition to the following development services for new IML products:

• Prototyping and Sampling

• Label Testing

• Short Production Runs |

|

|

|

|

|