|

Thinner, portable electronics push demand for slim glass

7/20/2011 |

|

|

According to WitsView, a research arm of Trendforce Corp., thinner and lighter product designs have become the driving force for slim glass panels. The hot sales of tablet PCs and mid-to-small size products also contributed to the growth in the demand for slim panels.

Because of the limitations of panel production in the past, glass substrate makers have been reluctant to increase product complexity because this can cause losses in production capacity. Thus, the thickness of glass substrates have been fixed among production lines for all generations of products.

According to WitView, the conventional thickness of traditional glass substrate in a Gen5 panel production line is 0.5mm. However, the growing demand for tablet PCs and the transfer of some mid-to-small size products to the Gen5 production line increased demands for 0.3mm or even 0.2mm slim glass.

To make thinner glass substrates, panel makers reduce the thickness of 0.5mm glass substrates and color filter them to 0.3mm or 0.2mm using the chemical etching method. But due to the increase in demand, the limited production capacity and increase in overall cost of chemical etchings, panel makers are considering making products directly on 0.3mm glass substrates.

Considering the high cost but low yield of equipment modification for 0.3mm, panel makers are thinking of a short-term plan to be able to address the growing demand. Panel makers are considering making 0.4mm glass substrate the conventional thickness for substrates in the Gen5 production line. They also plan to lower the overall production cost by reducing the time required for substrate thinning to 0.3mm.

WitsView believes that the diversified panel demands for associated glass substrates such as TFT substrate, LTPS substrate and cover glass, have changed the glass makers' attitudes toward glass thickness specifications. Through the production of slim glass, glass makers hope that they will be able to increase production volume without increasing capital expenditure for new glass furnaces. Increasing the production scale and capacity of slim glass will also enable keep the prices of slim glass low.

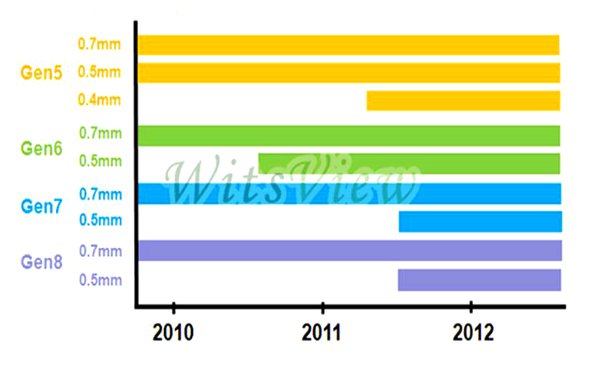

WitsView noted that the rising demand for slim glass will enable changes in panel production within the next two years. According to the research firm, shares above the Gen5 production line converted for the production of slim glass could reach roughly 25 percent this year. The number for Gen6 production could reach 30-35 percent due to the early introduction of 0.5mm glass substrates back in 2010. Along with the gradual conversion of the Gen5 production line to the production of 0.4mm glass substrate in the second half of the year, the overall annual conversion ratio could reach 20 percent with possibilities of moving to 0.3mm glass substrate in the future. The conversion ratio of Gen7 and Gen8 production line to the production of 0.5mm glass substrate this year is predicted to be lower than 5 percent due to the low yield of large-sized substrate production.

2011-2012 slim glass substrate conversion schedule of panel makers |

|

|

|

|

|