|

DSM's Stanyl® ForTii™ boosts connector performance at Amphenol East Asia, Taiwan

5/22/2012 |

|

|

Industry trends such as miniaturization, integration or "thinnovation", combined with the move towards Cloud Computing, will mean that areas such as the server market will depend increasingly on reflow soldering assembly technology. The required power supplies to drive each of these systems can easily reach 500V or more. As a consequence, plastic materials used in such server systems will need to meet stringent electrical, thermal and mechanical characteristics. DSM's Stanyl® ForTii™ shows exceptionally high performance characteristics with a very balanced profile on all of these requirements.

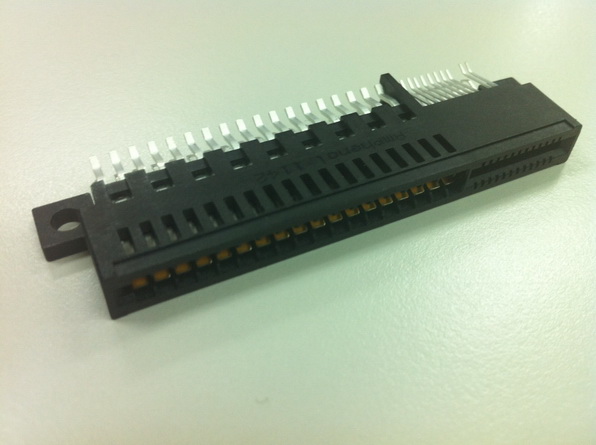

Most international connector manufacturers are applying the technology extensively and are developing various types of power related connectors. One such company is Amphenol, one of the largest manufacturers of interconnect products in the world. "For the Energy Edge Card connector, Stanyl® ForTii™ excels in mechanical strength and the material outperforms other high temperature polyamides or liquid crystal polymers at the wall breakage test." says Mr. Yuwen Chu, Senior Director of Engineering at Amphenol East Asia, Taiwan. "This is especially relevant, since our customers are constantly updating their product specification to meet even more severe test conditions, requiring an even higher strength for thin(ner) walls. In UL94 flammability testing, Stanyl® ForTii™ is the only polymer in this product family able to pass the stringent UL test."

The switch from the previous Energy Edge Card connector generation in LCP to Stanyl® ForTii™ also allows Amphenol to carry a higher current per connector pin compared to the current design. This will be in line with the upcoming increase in product specification by leading server OEMs. As a unique engineering material, Stanyl® ForTii™ flame retardant resins meet UL94-V0 classification, even down to wall thicknesses of 0.2mm, meeting not only the specifications of Amphenol customers for today, but also for tomorrow.

"Stanyl® ForTii™ offers customers such as Amphenol new design and material choices. We are proud to offer a halogen-free material with such high mechanical, thermal and electrical performance, which can be used for so many different applications." says John Chen, General Manager of Taiwan for DSM Engineering Plastics. "This is another example of DSM's Bright Science yielding an innovative solution, meeting the ever increasing market requirements on performance and sustainability. Our leadership is demonstrated by a complete portfolio of halogen-free engineering plastics, developed for a wide range of high-performance applications."

|

|

|

|

|

|