|

BOBST launches open platform to advance packaging production process

2/28/2021 |

|

|

In the current packaging environment, there is disruption. Not only from the COVID-19 pandemic, but also from ever-increasing competition and pressures around shorter times to market, smaller lot sizes, the need for perfect color consistency and quality control, and to fulfill corporate sustainability commitments.

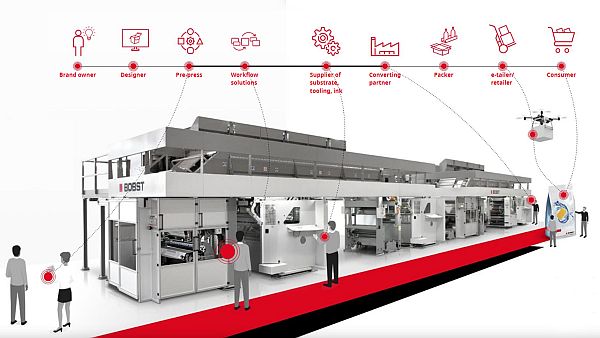

To bring connectivity, BOBST is helping to pioneer a fundamental transformation of the packaging value chain, from a series of isolated silos, to a connected end-to-end overview.

BOBST has announced its vision to shape the future of the packaging world and built a strategy based on four pillars: connectivity, digitalization, automation and sustainability.

Underpinning all of the individual solutions is BOBST Connect, an open platform that orchestrates the entire packaging production process and integrates all key components to make packaging production more effective.

"BOBST Connect is a one-stop platform that gives printers, converters and tool manufacturers access to our ecosystem of digital solutions utilizing state of the art Internet of Things (IoT) technology," stated Serge Morisod, Head of IoT Lab at BOBST.

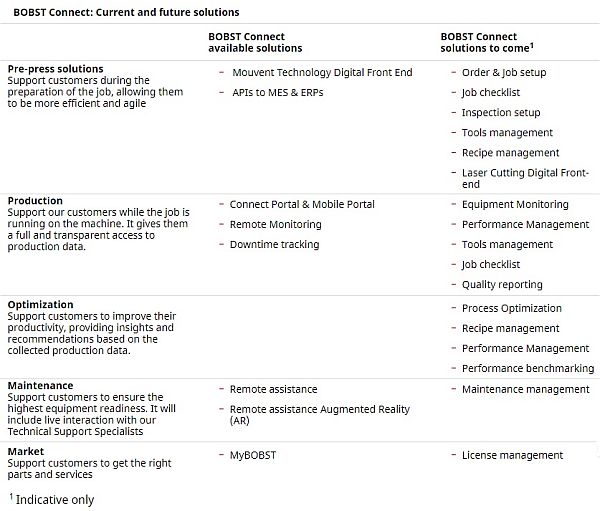

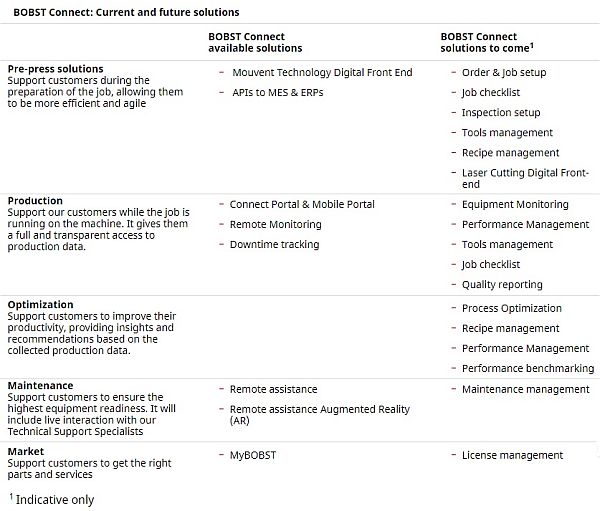

BOBST Connect covers five domains: pre-press, production, optimization, maintenance and market. There are several solutions already available across the domains and many more in the pipeline.

Some of the current BOBST Connect solutions include: Remote Monitoring, a comprehensive production reporting tool designed to quickly access detailed machine production, process and technical data; Remote assistance with Augmented Reality (AR), the first ever remote assistance service in the packaging industry to incorporate a smart headset with AR glasses; and MyBOBST, a personal portal for parts, order tracking, technical information, customer support, special offers and real-time machine data.

"As a first stage, we have established a range of solutions that help the converters to optimize connection and interoperability with other stakeholders in the value chain," said Serge. "New solutions will continue to become available as the platform constantly evolves, enabling our customers to continually adapt to the fast-changing environment."

Some of the solutions in the pipeline for 2021 include the introduction of recipe management in the pre-press stage for certain machines, and the introduction of equipment monitoring capabilities, performance management capabilities and quality control at the production stage. BOBST also plans to introduce the second generation of its popular remote assistance AR service in 2021.

|

|

|

|

|

|