|

First all-electric tube bender for leading European tube bending specialist

7/12/2011 |

|

|

includes laser correction system to meet demand for higher precision. Fig. Van Rijsoort bends tubes for a wide variety of applications, including ornamental furniture for gardens, parks and streets

Scarborough, UK, June 20, 2011 --- Unison has received an order for an all-electric tube bending machine from Van Rijsoort, the Netherlands-based tube bending specialists. The order follows an extensive investigation of tube bending technology by Van Rijsoort, during which the company joined a Unison Technology Tour and visited some of Unison's customers to gain an insight into how they are using all-electric tube bending techniques to reduce scrap, improve productivity and conserve energy.

Van Rijsoort is one of Europe's leading metal bending companies, with a long background in the architectural metalwork sector, and in manufacturing complex industrial tubular assemblies. Over 100 years old, the company has a history of investing in the latest forming and bending technology to help maintain its leading position, and nowadays operates a large number of machines on its manufacturing floor, including four hydraulically-driven tube benders and 10 round rail roll bending systems. However, this is the first time the company has invested in all-electric, servomotor-driven tube bending machinery.

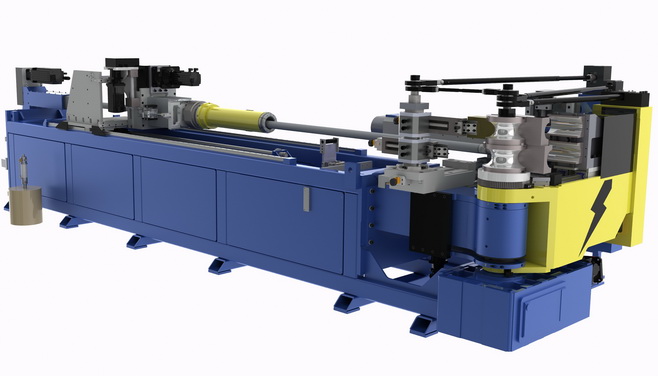

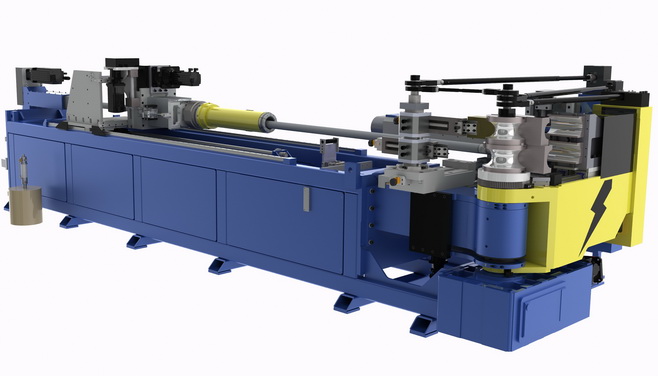

Van Rijsoort has ordered a large all-electric tube bending machine from Unison's Breeze 130 family.

According to Van Rijsoort's Financial Director, Martin Swinkels, "Some 60% of our production involves bending round tubes, for diverse applications ranging from building construction and general metalwork features like railings and staircases to large pipelines. And about two thirds of that work is on tubes with diameters below 130 mm. Our customers are demanding ever higher high levels of bend precision, which was our prime reason for looking at alternatives to hydraulic tube benders, which have reached the limit of their accuracy. We chose Unison for several reasons. Aside from a need to start migrating to more controllable tube bending machines that offer higher throughput, greater accuracy and better energy efficiency, we wanted to partner with a company that has a genuine history of innovation. We have found Unison to be extremely helpful, with an extensive knowledge of tube bending which it is prepared to share with customers."

The Breeze 130 tube bender ordered by Van Rijsoort is a high capacity multi-stack machine capable of bending up to 130 mm diameter tubes at rates of up to 36 degrees per second. Like all Unison all-electric tube benders, it only consumes significant amounts of power during the bending process itself, making it around an order of magnitude more energy efficient than a hydraulically-driven system.

This particular machine is equipped with a custom digital inclinometer, to automatically check the angle of three dimensional bends during manufacture, and with a unique laser correction system that overcomes the problem of variances in the 'spring-back' characteristics of metal tubes from different production batches or suppliers.

The laser correction system was one of Van Rijsoort's key technical reasons for ordering the machine. Some of its customers use robotic welding machines to fabricate items such as fences from sections of bent metal tubes, and if there is any inaccuracy in the bends, the sections are impossible to align correctly and are scrapped. Achieving the necessary bend accuracy for this application with hydraulic tube bending machines is proving increasingly difficult.

Photo shows an aerial view of Van Rijsoort's main facility and outside storage area.

Unison's laser correction system is entirely automatic - it measures bend angles by monitoring changes in the reflection distance using laser beams.

By evaluating the spring-back characteristics of the tubing material during the first bending operation, the system is able to automatically determine and accommodate the additional force required for all subsequent bends. This ensures that angles can be fabricated first time to very high accuracies, which will help Van Rijsoort meet production targets and reduce scrap significantly.

The new machine is due to be installed at Van Rijsoort's Klaaswaal, Netherlands facility in Q4 this year.

Note: Unison holds regular Technology Tours to help potential customers see the advantages of all-electric tube bending at first hand. Each tour includes visits to customers and a technical tube bending workshop. For more details, please visit: http://www.unisonltd.com/tour.html |

|

|

|

|

|