|

Kistler is setting new standards for electromechanical NC joining systems with the maXYmos NC

3/10/2015 |

|

|

Extending the maXYmos product range to control and monitor production processes and quality assurance

Guangzhou, 10 March 2015 - At SIAF 2015 from 9-11 March, Kistler will be showcasing a new joining system comprising maXYmos NC, the IndraDrive servo amplifier and established and proven NC joining modules. The newly developed maXYmos NC monitors and controls the joining process. Equipped with an intuitive touch display, the new system is particularly easy to use, while the integrated sequence control offers a high level of flexibility for straightforward to highly complex joining processes.

Process control made easy

The XY monitors from Kistler's maXYmos series enable customers to visualize and evaluate production processes - allowing them to operate in a consistent, process-integrated manner and to maximize quality assurance. In doing so, they monitor XY curves, where two measured variables must be in a certain relation to each other. Force-displacement curves are a good example of this, which arise from bearings being press-fitted. A further development to the maXYmos product range, the maXYmos NC (Numeric Control) enables NC joining systems to now also be monitored and controlled. Such NC joining systems are predominantly used in the automotive and supply industry in the widest range of manufacturing processes, such as gearbox, motor, chassis or pump installation. The maXYmos NC evaluates and documents the XY curves of joining and press-fitting operations in combination with NC joining modules and the associated IndraDrive servo amplifier. Due to the form of measurement curves, each stage of the production and assembly line - and even the entire product - can be monitored and operated via SERCOS III all in real time. In this way, optimum cycle times can be achieved with the highest degree of repeat accuracy. Unplanned downtimes are minimized as machine availability increases, in turn allowing the productivity of the manufacturing process to be accelerated.

Increased flexibility for users

The integrated sequence control (Sequencer Mode) enables processes to be illustrated without the need for expensive, external PLC programming. Indeed, the programs are set up in a swift, straightforward manner using the intuitive user interface of the touch display. In total, up to 128 programs can be stored, with the option of defining each one with an independent sequence of up to 255 elements. As a result, even highly complex processes can be illustrated simply and effectively. Such processes are evaluated by means of the curve patterns of two measured variables in relation to one another, which are then rated as good (OK) or bad (NOK). For that purpose, ten evaluation objectives are available in each program. Process deviations are reliably detected, while complex process sequences are regulated and controlled. Moreover, the new Multi-View function can be used to simultaneously visualize and compare various processes on the same monitor.

Easily integrated and intuitively operated

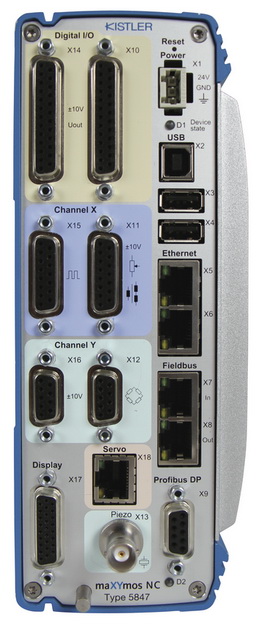

The flexible housing concept of maXYmos monitors allows easy integration into existing or newly developed systems. The maXYmos NC comprises two components, the measuring and evaluation module (MEM) and the display module (DIM). These two components can either be installed separately or as a compact unit. Moreover, up to eight joining processes can be visualized on the same display. As such, this guarantees maximum flexibility during installation, whilst saving space and contributing towards an optimum cost-benefit ratio. Furthermore, the measuring and evaluation module (MEM) ticks all the boxes in terms of its variety of interfaces. The most common interfaces such as PROFIBUS, PROFINET, EtherNet/IP and EtherCAT are integrated and can be selected via a menu on the touch display. This allows users to respond to changing requirements in relation to sensor or fieldbus types. In addition, the standardization of MEM development keeps costs for spare part handling to a minimum.

Kistler is presenting the maXYmos NC at SIAF in Guangzhou, China from 9-11 March 2015 at stand C01, hall 5.2.

Image 1: The uniform philosophy of the maXYmos product family provides user-friendly and intuitive operation. It supports simple and quick start-up of the electro-mechanical NC joining systems.

Image 2: The measuring and evaluation module (MEM) ticks all the boxes in terms of its variety of interfaces. All the standard interfaces are continuously available, ensuring flexibility in the event that the requirements placed on sensor or fieldbus types change, as well as offering considerable advantages in terms of spare parts stocking.

Image 3: The maXYmos NC controls the NC joining module via the servo amplifier through the integrated sequence control. An independent sequence can be defined for each of the 128 programs. |

|

Related Exhibition:

|

|

|

|

|

Expodent Chennai 2025

|

Largest Dental Exhibition in South India

4/19/2025 - 4/20/2025

Venue: Chennai Trade Centre, Chennai, India

|

|

|

|

|

|

|