|

More powerful, more energy-efficient, more versatile

9/15/2014 |

|

|

- The expanded product portfolio of KraussMaffei reinforces the company's technological leadership in injection molding

- The all-electric AX series has been expanded to include two new greater clamping forces

- New GX series with multi-component design

- Marketing to begin at Fakuma 2014

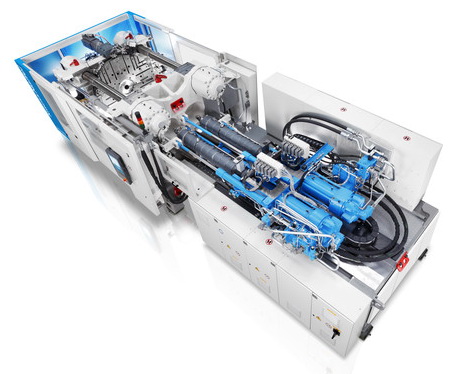

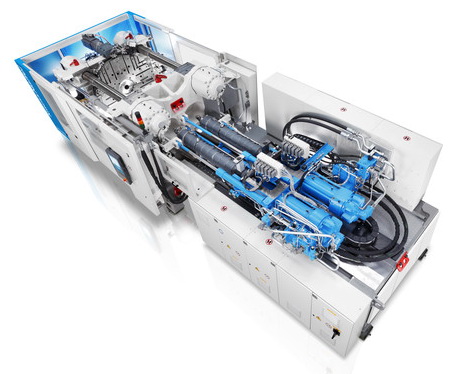

(Munich, 3 September 2014) With two new sizes in the clamping force range of 4,500 and 5,500 kN, KraussMaffei is expanding its product portfolio in the all-electric injection molding machine segment of the AX series. The further addition of three new machine models for the hydro-mechanical twin-platen injection molding machine in the GX series increases brand presence in the area of multi-component injection molding. With these additions, KraussMaffei increases its comprehensive and high-performance product portfolio in the mid-size machine segment between 4,000 and 9,000 kN. Marketing of the new products is expected to begin at Fakuma 2014.

Broad and high-performance product portfolio

"Our customers are increasingly asking for high-performance, energy-efficient and simultaneously space-saving solutions. With this in mind we are working continuously on the expansion and continued development of our broad portfolio of all-electric, hydraulic and hybrid injection molding machines. With five series and more than 50 different base machine models, we offer our customers application-specific solutions for every production challenge. With this diversity we are an industry leading system supplier", explains Dr. Hans Ulrich Golz, President of the Injection Molding Machinery segment of the KraussMaffei Group. With the new sizes of the AX series, together with the new GX variants, the company is setting the standard in energy-efficient, all-electric injection molding machines in the mid-size machine segment and in multi-component technology.

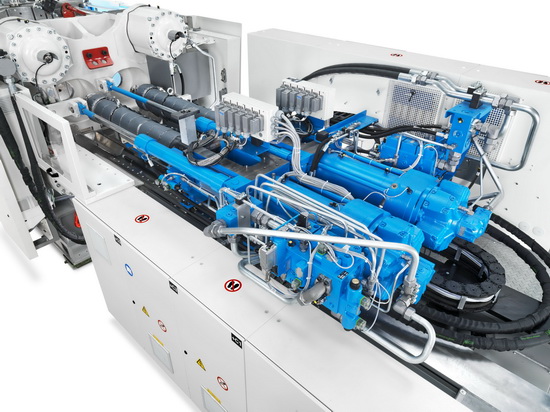

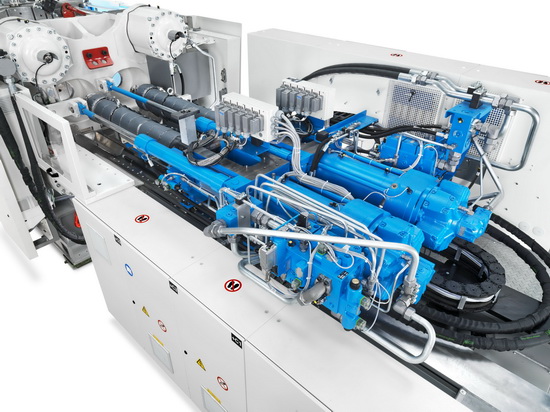

Photo 2: Compact and powerful: the new KraussMaffei multi-component injection molding machine GXH with parallel injection units.

The world leader in energy savings: AX in class 9+

New to the AX series product group are the AX 450 and the AX 550, with which KraussMaffei can offer all-electric injection molding machines expanded for greater clamping force from 4,500 kN or 5,500 kN. "We are noticing an increasing demand for all-electric injection molding machines with large locking forces. The new AX 450 and AX 550 perfectly complement our product line of all-electric standard machines. Thus our customers can take full advantage of the AX series with regard to precision and energy efficiency in the large machine range", says Jochen Mitzler, Head of Strategic Product Management for KraussMaffei. All-electric AX series injection molding machines feature resource-efficient manufacturing with high repeatability. They earn an energy efficiency rating of 9+ according to the Euromap 60.1 standard. Against comparable hydraulic injection molding machines, energy consumption is often reduced by 50 percent or more.

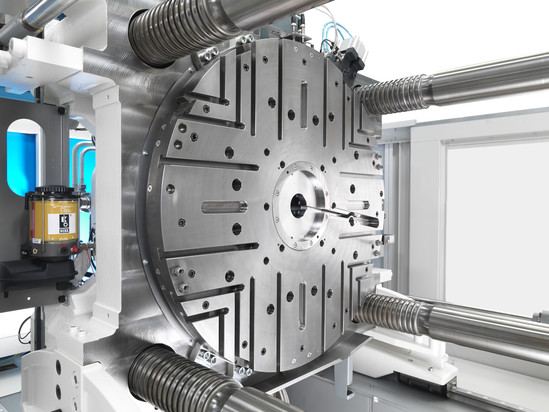

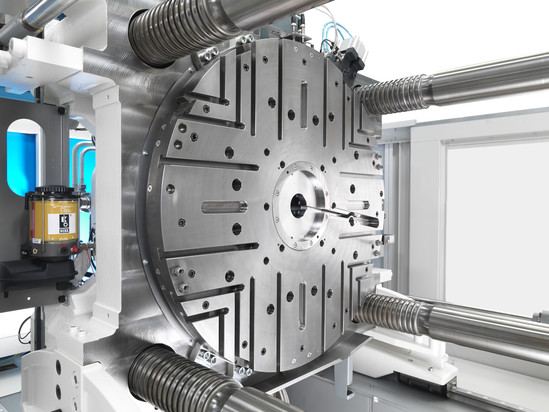

Photo 3: The parallel oriented injection units allow for a simplified mold design and improved accessibility to the plasticizing unit.

Application-specific solutions for multi-component injection molding

KraussMaffei is the global leader in multi-component injection molding. "With the Multinject technology based on the CX, GX, and MX series we cover the market as the only provider of small, mid-size, and large clamping force options from 350 to 55,000 kN", says Golz. Three new variants have been added to the twin-platen injection molding machines in the KraussMaffei GX series: the new GXH, GXL and GXV offer optimal prerequisites for multi-component injection molding and add to the GXW (SpinForm reversing plate technology), which was successfully introduced into the market at K 2013. Another highlight is the new integrated turntable. A servo-electric drive unit ensures especially fast rotations, parallel movement and precise positioning.

Depending on requirements and product the customer can select suitable positioning of the injection units and the optional turntable. The H in GXH stands for the symbolic arrangement of two or more injection units in parallel. "Through the horizontal arrangement the melt is guided directly into the respective mold-half. This way, so-called dead corners in the hot runner are reduced", says Mitzler. Additional advantages of injection units arranged in parallel are the simplified mold design and space-saving design of the entire machine. Typical end applications of GXH are found in the manufacture of technical and optical vehicle components. 2-component screw-cap closures for the packaging industry can also be produced efficiently. Advantages of the GearX locking mechanism and the GuideX guide shoe developed by Krauss Maffei are apparent in fast cycle times with minimal energy consumption.

Photo 4: The new servo-electric turntable is integrated into the clamping platen. High mold weights, fast rotations and precise positioning ensure cost-effective production.

The L in GXL on the other hand stands for the lateral horizontal positioning of the second injection unit. Thanks to the modular design of the GX series, small and large shot weights can be implemented. Third in the group is the new GXV with vertical positioning of the second injection unit, which allows access to the main injection unit. The V injection unit can be moved entirely out of the clamping unit area for the mold change to substantially improve accessibility.

Rigid-flexible pairings, color soft-touch surfaces, functional integration and the combination of various colors and plastics, such as thermoplastics, elastomers, and polyurethanes, are possible with the new GX series multi-component injection molding machines from KraussMaffei. Not only two, but up to four different components can be processed. "The requirements of multifunctional components consisting of three or more materials continue to increase. The modular configuration of additional injection units make 3- or 4-color machines an easy possibility. All units are controlled centrally by the KraussMaffei MC6 control system", Mitzler adds.

KraussMaffei at Fakuma: Hall A7, Booth 7303/7304 |

|

Related Exhibition:

|

|

|

|

|

FAKUMA 2014

|

23rd International Trade Fair for Plastics Processing

10/14/2014 - 10/18/2014

Venue: Friedrichshafen Exhibition Centre, Friedrichshafen, Germany

|

|

|

|

|

|

|